Automatic Peristaltic Pump Rotary Type Dropper Bottles Filling Capping Machine

Main Technical Parameters:

Overview:

Accessory Brand:

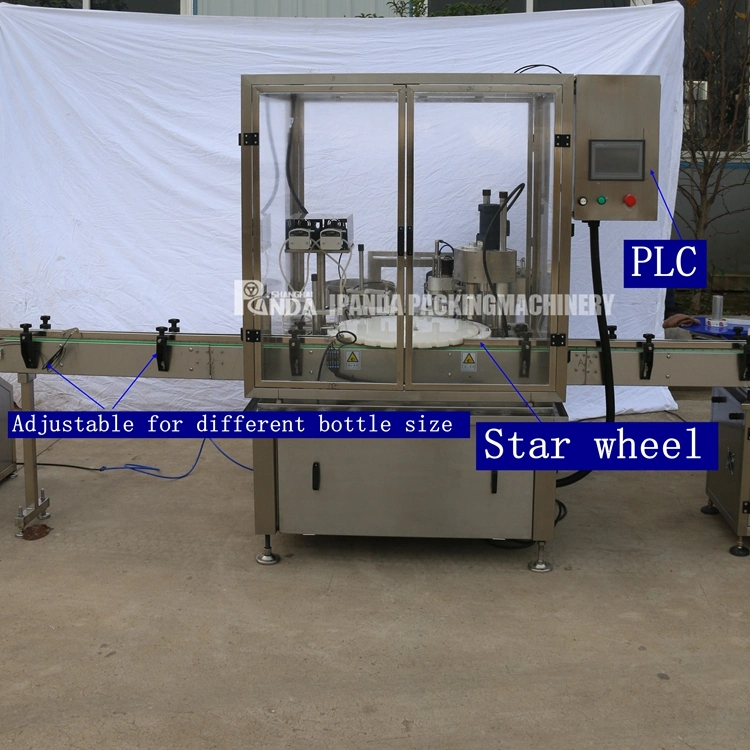

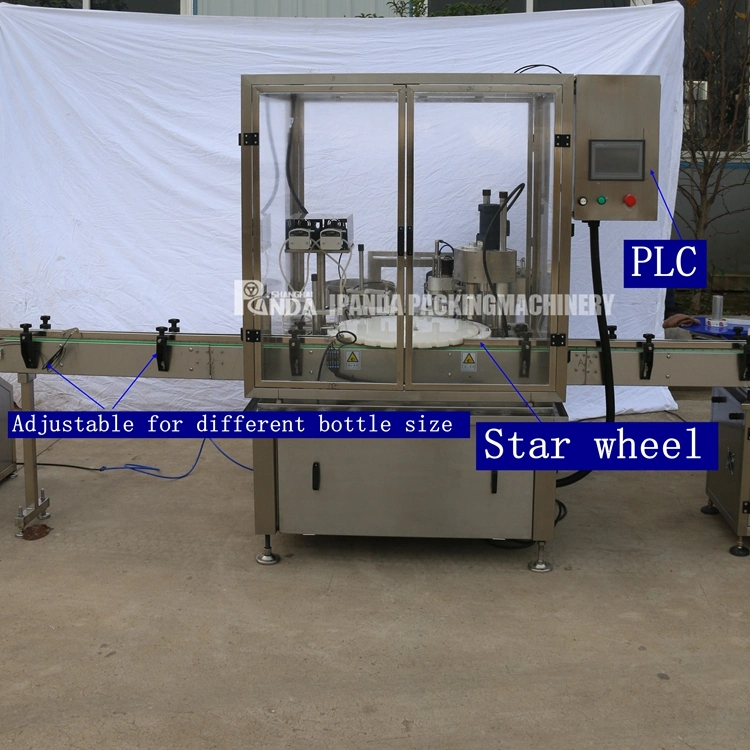

The Detailed Pictures:

Company Introduction:

Shanghai iPanda Intelligent Machinery Co., Ltd. is committed to the equipment R&D, manufacture and trade of various types of packaging machinery. It is a high-tech enterprise integrating design, manufacture, trade , and R&D. The company's equipment R&D and manufacture team has more than 10 years of experience in the industry, accepting unique requirements from customers and providing various types of automatic or semi-automatic assembly lines for filling. Products are widely used in daily chemicals, medicine, petrochemical, foodstuff, beverage and other fields. Our products has a market in Europe, the United States and Southeast Asia, etc. won the new and old customers alike.

The talent team of Panda Intelligent Machinery gathers product experts, sales experts and after-sales service staffs, and upholds the business philosophy of "Good quality , Good service, Good prestige". We will continue to improve our own business level, expand our business scope, and strive to meet the needs of customers.

Transportation:

Our Services:

1. We can supply OEC/ODM design.

2. We offer 1 year warranty and free spare parts supply(not man-made broken),we will also prepare enough spare parts delivered

together with the machines.

3. Our machine is designed in simple structure,so that easy for operation anddebugging.

4. Engineers available to service machinery overseas

5. Field installation, commissioning and training. Field maintenance and repair service.

FAQ:

Q1: Are you factory or trading company?

A: We are factory.

Q2: Can you guarantee your quality?

A: Of course. We are the manufacture factory. More importantly, we put a high value on our reputation. Best quality is our

principle all the time. You can be assured on our production completely.

Q3: What should I do if we are not able to operate the machine when we receive it?

A: Operation manual and video demonstration sent along with the machine to give instructions. Besides, we have professional

after-sale group to customer 's site to solve any problems.

Q4: How could I get the spares on machines?

A: We will send extra sets of easy broken spares and accessories like O ring etc. Non-artificial damaged spares will be sent freely

and shipping free during 1 year's warranty.

| Applied Bottle | 5-200 ml |

| Productive Capacity | 30-80pcs/min |

| Filling Tolerance | ±1% |

| Qualified Stoppering | ≥99% |

| Qualified cap putting | ≥99% |

| Qualified capping | ≥99% |

| Power Supply | 380V ,50HZ |

| Power | 1.5KW |

| Net Weight | 500KG |

| Dimension | 2500(L)×1000(W)×1700(H) |

Overview:

The E-liquid filling machine- normally cap is a high-tech product researched and developed by our company. It is suitable for products of liquid such as oral liquid, e-liquid, eye drop etc. It is widely applied for filling of products in such industries as food, cosmetics, medicine, grease, daily chemical industry, detergent, pesticide and chemical industry etc.

Features:

1. This machine adopts constant torque screw caps, equipped with automatic sliding device, to prevent the cap damage;

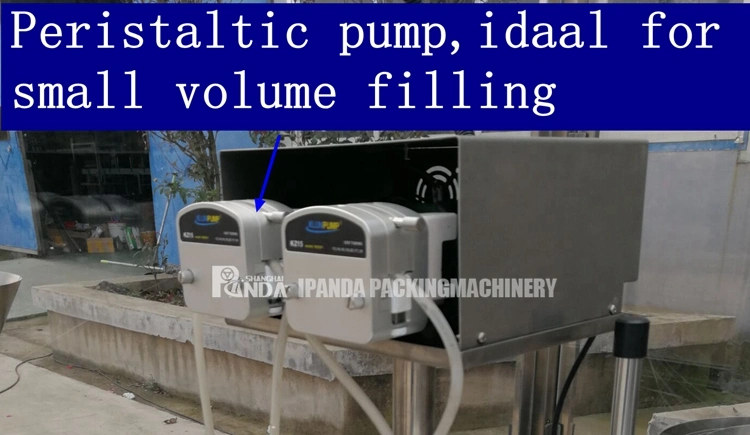

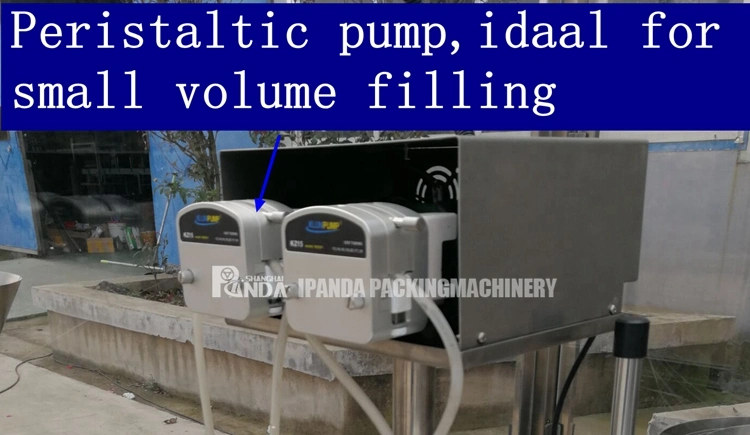

2. Peristaltic pump filling, measuring precision, convenient manipulation;

3. Filling system has function of suck back, avoid liquid leak through;

4. Color touch screen display, PLC control system, no bottle no filling, no adding plug, no capping;

5. Adding plug device can choose fixed mold or mechanical vacuum mold;

6.Machine is made by 316 and 304 stainless steel, easy to dismantle and clean, full compliance with GMP requirements.

2. Peristaltic pump filling, measuring precision, convenient manipulation;

3. Filling system has function of suck back, avoid liquid leak through;

4. Color touch screen display, PLC control system, no bottle no filling, no adding plug, no capping;

5. Adding plug device can choose fixed mold or mechanical vacuum mold;

6.Machine is made by 316 and 304 stainless steel, easy to dismantle and clean, full compliance with GMP requirements.

Accessory Brand:

Machine Frame | SUS304 Stainless Steel | |

The parts which contact liquid | SUS316L Stainless Steel | |

Main Motor | ABB | Switzerland |

Inverter | Mitsubishi | Japan |

Air Switch | Schneider | France |

Contactor | Schneider | France |

Relay | Omron | Japan |

OFA | Autonics | Korea |

Bearing | IGUS | Germany |

CAM Indexer | Shangdong | China |

Turntable | Plastic POM | Japan |

Cylinder | AIRTAC | Taiwan |

Touch Screen | Siemens | Germany |

PLC | Siemens | Germany |

Servo Motor | Delta | Taiwan |

The Detailed Pictures:

Warm Tip:

1. If out of filling volume range, we could customize for you.

2. If need higher capacity, please reach us to customize the machine with more filling nozzles.

Shanghai iPanda Intelligent Machinery Co., Ltd. is committed to the equipment R&D, manufacture and trade of various types of packaging machinery. It is a high-tech enterprise integrating design, manufacture, trade , and R&D. The company's equipment R&D and manufacture team has more than 10 years of experience in the industry, accepting unique requirements from customers and providing various types of automatic or semi-automatic assembly lines for filling. Products are widely used in daily chemicals, medicine, petrochemical, foodstuff, beverage and other fields. Our products has a market in Europe, the United States and Southeast Asia, etc. won the new and old customers alike.

The talent team of Panda Intelligent Machinery gathers product experts, sales experts and after-sales service staffs, and upholds the business philosophy of "Good quality , Good service, Good prestige". We will continue to improve our own business level, expand our business scope, and strive to meet the needs of customers.

Transportation:

Our Services:

1. We can supply OEC/ODM design.

2. We offer 1 year warranty and free spare parts supply(not man-made broken),we will also prepare enough spare parts delivered

together with the machines.

3. Our machine is designed in simple structure,so that easy for operation anddebugging.

4. Engineers available to service machinery overseas

5. Field installation, commissioning and training. Field maintenance and repair service.

FAQ:

Q1: Are you factory or trading company?

A: We are factory.

Q2: Can you guarantee your quality?

A: Of course. We are the manufacture factory. More importantly, we put a high value on our reputation. Best quality is our

principle all the time. You can be assured on our production completely.

Q3: What should I do if we are not able to operate the machine when we receive it?

A: Operation manual and video demonstration sent along with the machine to give instructions. Besides, we have professional

after-sale group to customer 's site to solve any problems.

Q4: How could I get the spares on machines?

A: We will send extra sets of easy broken spares and accessories like O ring etc. Non-artificial damaged spares will be sent freely

and shipping free during 1 year's warranty.