Liquid Sealing Packaging Filler with Peristaltic Pump Controlling

| No. | Name | Unit price | Qty | Total Price | Remark |

| 1. | Bottle unscrambler | 1,094 | 1 set | 1,094 | SUS304, 900mm diameter |

| 2 | 12 heads servo piston filling machine | 17,941 | 1 set | 17,941 | Filling accuracy: ±0.5ml(30ml); filling material: no viscous liquid |

| 3 | Cap screwing machine | 6,176 | 1 set | 6,176 | 100BPM capacity |

| Total: | EXW: 25,211 .00 USD | ||||

1 Bottle sorter:

This bottle unscrambler is a rotary worktable with speed control. The machine is used as a buffer platform applying for intermediate connection of assembly line to reduce the length of conveyor. Both the range of bottle and the speed can be adjusted freely, which is benefit for the production. Its procedure: put bottles onto round turntable, then turntable rotate to feed bottles onto convey belt.

This bottle unscrambler is a rotary worktable with speed control. The machine is used as a buffer platform applying for intermediate connection of assembly line to reduce the length of conveyor. Both the range of bottle and the speed can be adjusted freely, which is benefit for the production. Its procedure: put bottles onto round turntable, then turntable rotate to feed bottles onto convey belt.| Applicable Bottles | Plastic Bottles/Glass Bottles |

| Product Capacity | 30-120 Bottles Per Minute |

| Dimension | 900mm(Customized) |

| Weight | 85KG |

| Voltage | AC220v/380v |

2 12 heads servo piston filling machine:

1).This machine operates easily, with compact structure, perfect control system and high level of automation.

1).This machine operates easily, with compact structure, perfect control system and high level of automation.2). The parts contacting with product is made of high quality stainless steel, anti-corrosive, and easy to clean.

4). By adopting high speed filling valve, the liquid level is precise and no waste is to increase. That guarantees the demand of modern filling technology.

5). Import PLC control servo motor ensure filling accuracy.

6). By adopting overload protection system, it can ensure the protection of safety of the operator and equipment.

7). The electric equipment and pneumatic parts are of brand name of the world.

Maily electrical equipment:

| PLC | Taiwan, Delta |

| Touch screen | Taiwan, Weinview |

| servo motor | Taiwan, Delta |

| Frequency converter | Taiwan, Delta or France, Schneider |

| Low-voltage electricals | France, Schneider |

| Pneumatic components | Taiwan, Airtac |

| Conveying motor | France, Schneider |

| Photoelectricity | Japan, Keyence or Germany Sick |

| cylinder | Taiwan, Airtac |

Mainly parameter:

| Item | GHAGF-12 |

| Filling nozzles | 12 |

| Filling range | 25~30ml(customized) |

| Filling accuracy | ±0.5ml |

| Air pressure | 0.6-0.8mpa |

| Voltage | 220v 50/60hz |

| Size | 2000*900*2200 |

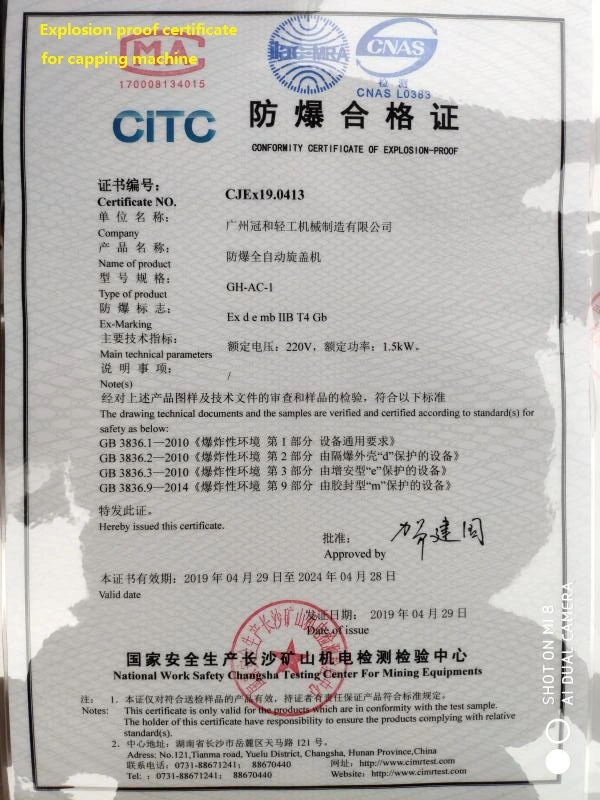

3 Screwing cap machine:

This multifunction capping machine is suitable for various shape screwing and spray pump caps. It is wildly used for cosmetic, detergent product pesticide industries. Easy operation, width adjusting score, with high efficient quality.

This multifunction capping machine is suitable for various shape screwing and spray pump caps. It is wildly used for cosmetic, detergent product pesticide industries. Easy operation, width adjusting score, with high efficient quality.Feature:

- PLC control system, with highly automatic

- Torsion control. Different size cap adjust different torsion.

- Made of SUS304, more durable in usage.

| Voltage | 220v 50/60hz |

| Size | 3000×1150×1700 |

| Air pressure | 0.5-0.7pa |

| Capping range | 20-50mm |

| Weithg | 400kg |

Mainly parameter:

| Frequency converter | Taiwan, Delta or France, Schneider |

| Low-voltage electricals | France, Schneider |

| Photoelectricity | Japan, Keyence or Japan, Keyence or Germany Sick |

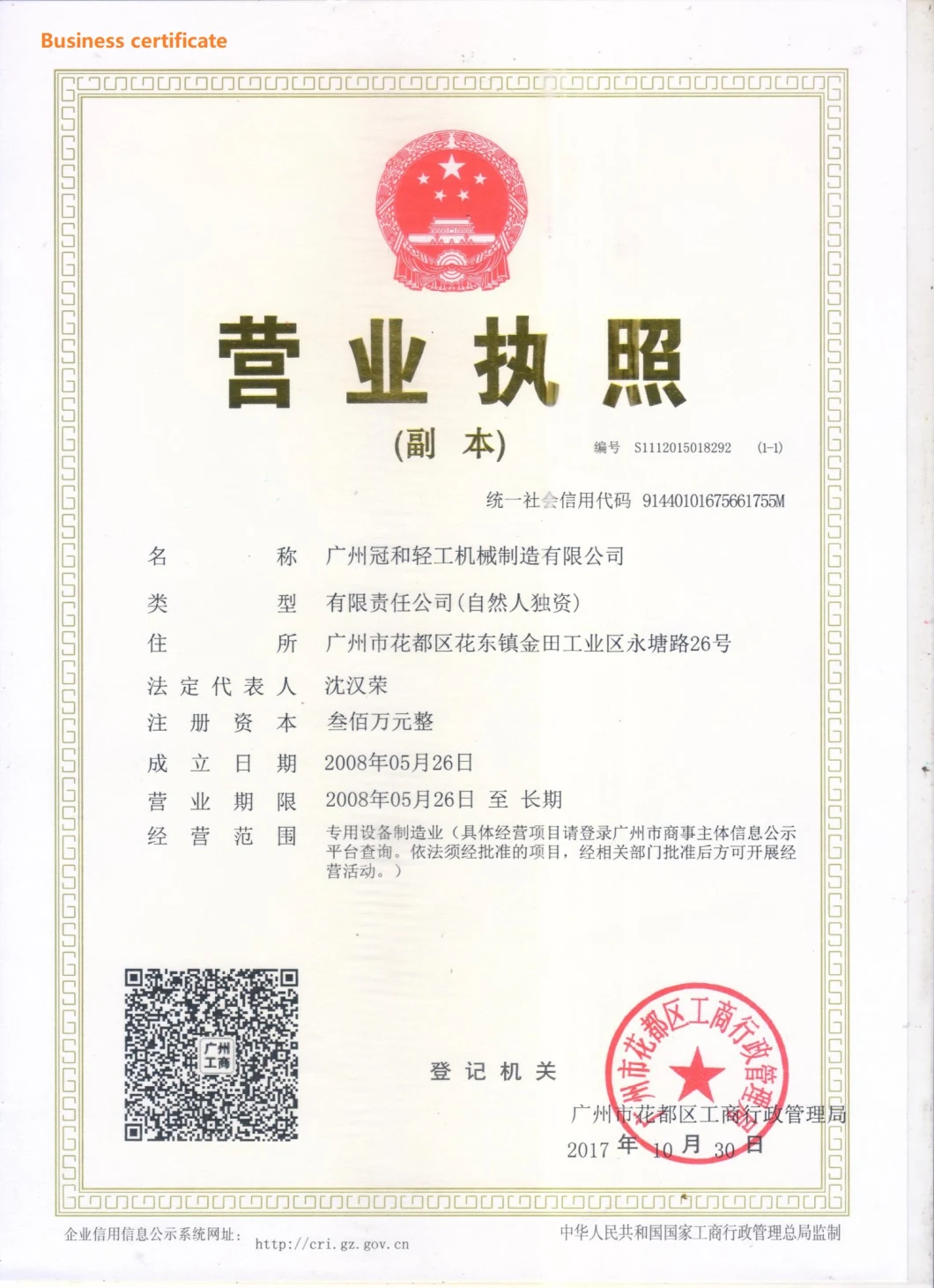

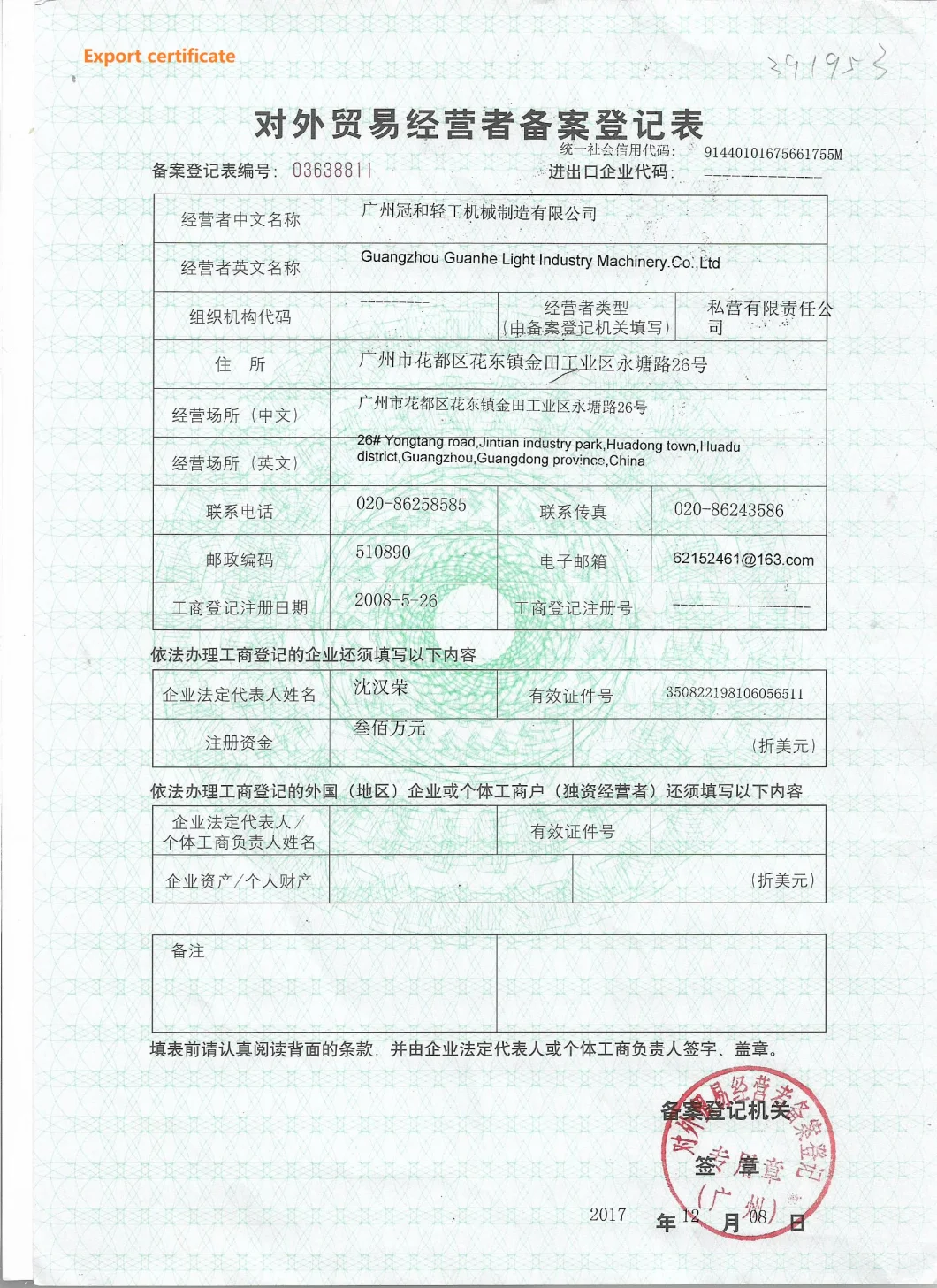

Our factory's profile: